Apple chip supplier is busy producing cutting-edge chips

In what might be a positive sign for a turnaround in smartphone demand, DigiTimes reports that Taiwan Semiconductor Manufacturing Company (TSMC) has tripled the lead time it needs to churn out chips using its 7nm process. The company is the largest foundry in the world and manufacturers chips designed by companies without the facilities required to produce these chips themselves. That would include firms like Apple, Huawei, and Qualcomm. TSMC said that last year it was "manufacturing 10,436 different products using 261 distinct technologies for 481 different customers," but Apple is responsible for the largest percentage of its annual revenue.

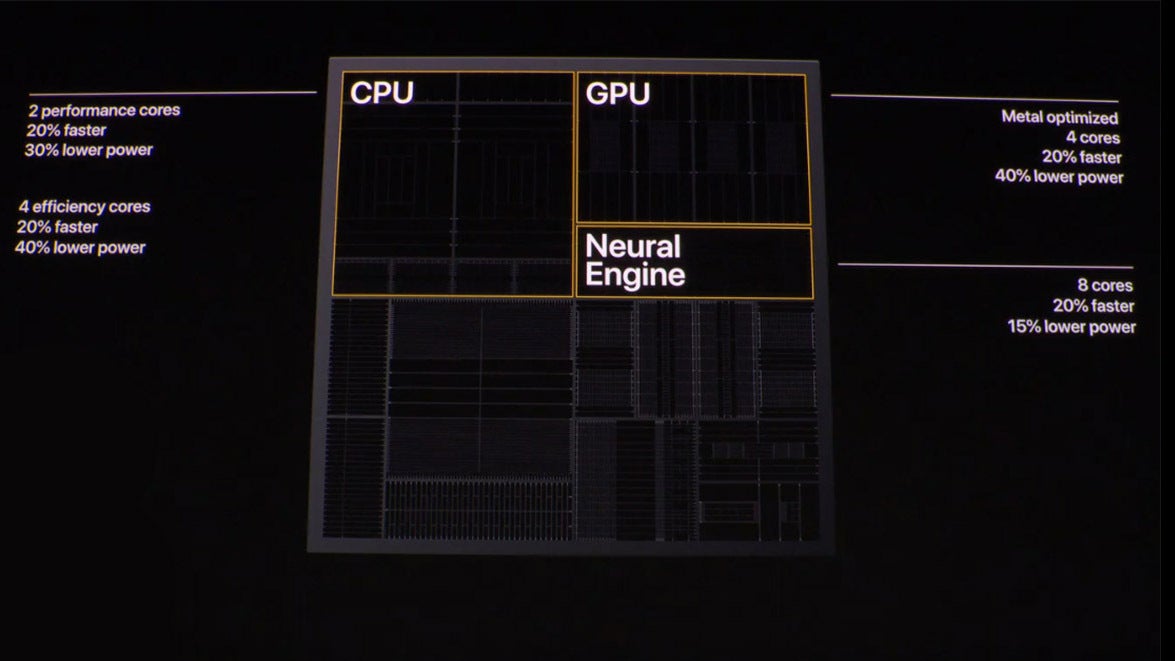

The 7nm process refers to the number of transistors that fit inside an integrated circuit; the smaller the number, the more transistors inside. And the more transistors inside a chip, the more powerful and energy-efficient it is. Consider that the 5G version of Huawei's Kirin 990 SoC contains 10.3 billion transistors. Next year, TSMC should start rolling 5nm chips off of its assembly line and these components will include 171.3 million transistors per square millimeter. And 3nm chips could be a reality by 2022.

Lead time for 7nm production has tripled from two months to six months

The lead time is now six months, up from two months, which means that TSMC's customers will have to get their orders in earlier if they want to maintain a steady supply of chips. The foundry says that the longer lead time is only required for customers shifting to 7nm from a larger process node, or for those who are expanding capacity. TSMC is believed to have given Apple priority for its 7nm needs which is one of the reasons why such lead times have tripled. It would appear that other companies have had to rush to place their orders before Apple took over the 7nm node.

The Apple A13 Bionic is manufactured by TSMC using its 7nm process

Back in 2015, both TSMC and Samsung manufactured the A9 chip that powered the Apple iPhone 6s and iPhone 6s Plus. Since then, only TSMC has been given the assignment of churning out the chipsets used on the iPhone. Apple obviously needs a foundry that can deliver chips in the quantity and quality it needs for its smartphones. Since Apple started relying solely on TSMC for 2016's iPhone 7 and iPhone 7 Plus, the tech giant seems totally content with the company.

While business has been booming at TSMC, smartphone sales this year are expected to drop by 3.8%. But it seems that the longer lead time at TSMC is foreshadowing a turnaround in 2020. Gartner forecasts a 1.5% increase in smartphone sales next year. The increasing demand for 5G handsets that many expect to start in 2020 could be one of the reasons for TSMC's full dance card; some of the 7nm production includes 5G modem chips.

TSMC is losing a major customer in 2020, but just for one year. Samsung, which has its own semiconductor fabrication facilities, is expected to produce the Snapdragon 865 Mobile Platform. But the following year, it will be back to TSMC for the 5nm Snapdragon 875 Mobile Platform.

TSMC is in the middle of a legal battle with GlobalFoundries. The latter claims that TSMC infringed on 16 of its patents and filed suit against the foundry in the U.S. in Germany. In its filing submitted with the International Trade Commission (ITC), GlobalFoundries asked for an injunction against the importation into the U.S. of devices that might have been produced illegally using its IP. That would ban several iOS and Android devices from being shipped into the U.S. TSMC has denied the claim and said that it "will fight vigorously, using any and all options, to protect our proprietary technologies."

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: