TSMC and Apple reportedly discussed 2nm chips for future iPhone models

Last year, Apple became the first phone manufacturer to use a chipset manufactured using the 5nm process node to drive a handset. The process node reflects the number of transistors that can fit in a square mm. The higher this transistor density, the more powerful or energy efficient a chip is. For example, the 7nm A13 Bionic chip had a transistor density of nearly 900 transistors per square mm. Overall, that chip sported 8.5 billion transistors inside (known as the transistor count). The 5nm A14 Bionic fits 134 million transistors into a square mm, a 49% improvement over the A13 Bionic's transistor density. Overall, the chip has 11.8 billion transistors inside.

Apple has been in discussions with TSMC over 2nm chips that could be ready to be released by 2024

TSMC, the world's largest contract foundry, will reportedly rollout 3nm chips this year under risk production. The companies buying these chips understand that they might need some tweaking before regular production begins. 3nm chips are expected to use 25%-30% less energy while delivering 10% to 15% higher performance at the same power levels. According to PatentlyApple, TSMC is planning to move its 3nm chips to Baoshan, Hsinchu. This was supposedly done to help TSMC secretly accommodate a huge order for 3nm chips from Intel. A report published by Digitimes in January claims that Intel will replace Huawei as TSMC's second largest customer (after Apple, of course); unlike past years when Intel's non-core products were outsourced to TSMC, this year Intel will have TSMC produce high-end chips using its 3nm process node starting in the second half of 2022.

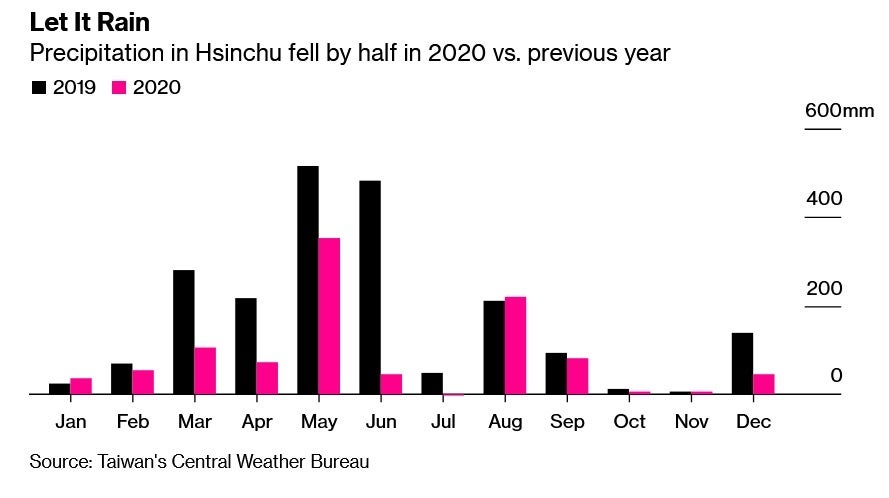

The amount of rainfall in a key Taiwan city fell sharply last year

The report adds that Apple and TSMC have already discussed site preparation and tech R&D with related to 2nm production. Apple has already come to an agreement with TSMC to procure the 3nm chips that might debut on the 2022 iPhone 14 line. By 2024, we might see the 2nm A18 Bionic inside the iPhone 16 series.

Perhaps we shouldn't be too eager to look so far ahead. Mother Nature might deprive the Taiwan based chip industry of a key "component" needed to build chips within months. Bloomberg stated on Monday that the semiconductor industry in Taiwan only has enough water reserves to keep facilities running until May; that is when monsoon rains are expected to bust the worst drought that the country has seen in 56 years. TSMC has cut usage of water and has ordered small truckloads of H2O to prepare for restrictions, but there could be some problems if Taiwan does not get the kind of rain it normally does during the spring and summer. Creating an integrated circuit on a 30cm wafer (nearly 12-inches) requires the use of 2,200 gallons of water. Hsinchu City, home to TSMC, received just half the amount of rain in 2020 than it did the year before.

Thanks to conversation methods, Taiwan has 701 million tons of water giving it enough of the wet stuff until May. In the country, 16 billion to 17 billion tons of water are used annually.

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: