Korean researchers make 'the world's first imprintable and bendable lithium-ion battery'

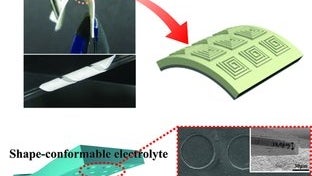

Flexible screens? Check. Flexible chassis and PCBs? Check. Flexible batteries? Checked now. Korean researchers have come up with a process to make "a class of imprintable, bendable, and shape-conformable polymer electrolyte with excellent electrochemical performance in lithium battery system."

These can be sprayed on electrodes, then baked with UV rays for about 30 minutes to create power units - much faster than the traditional way of making lithium-ion cells.

Prof. Lee Sang-young of South Korea's Ulsan National Institute of Science and Technology is the read of the project, working alongside nine more scientists from different places, like Prof. John A. Rogers of the University of Illinois. The Korean Ministry of Education, Science and Technology, which is co-sponsoring the research, said in a press release:

Conventional lithium-ion batteries that use liquefied electrolytes had problems with safety as the film that separates electrolytes may melt under heat, in which case the positive and negative may come in contact, causing an explosion.

Because the new battery uses flexible but solid materials, and not liquids, it can be expected to show a much higher level of stability than conventional rechargeable batteries.

Because the new battery uses flexible but solid materials, and not liquids, it can be expected to show a much higher level of stability than conventional rechargeable batteries.

The kicker compared to some other flexible batteries we've seen, and even conventional batteries - these are stable, even under high temperatures, and easier to manufacture, which is crucial for production versions of the bendy power cells. Stanford also has come up with a non-rigid battery, which you can see demonstrated in the video below, but the new invention sounds much easier to place into a shape-shifting phone at some point.

We are hoping that Samsung is already prepping a grant for the continuation of the research to facilitate the marriage of the bendable cellies with its YOUM brand of flexible displays. What particularly struck us as useful for bendy phones, was the following from the research publication abstract:

The unique structural design and well-tuned rheological characteristics of the UV-curable electrolyte mixture, in combination with direct UV-assisted nanoimprint lithography, allow the successful fabrication of polymer electrolyte in geometries not accessible with conventional materials.

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: