TSMC's U.S. fab faces delays while the final plan could end up being more ambitious

As you probably already know if you are a loyal PhoneArena reader, the largest independent foundry in the world, TSMC, is building a fabrication facility in Phoenix, Arizona that is supposed to turn out 5nm chipsets by 2024. The facilities will not be turning out cutting-edge chips since TSMC could be delivering 2nm chips out of its fabs in Taiwan by the time 5nm product rolls off of its assembly lines in Arizona.

U.S. wants to be self-sufficient when it comes to purchasing chips

According to a report by wccftech, TSMC is facing a huge management shakeup that could potentially lead to a delay in the completion of the new facility. As with any chip fab, TSMC needs to make sure that its production facilities include clean rooms where there is zero-tolerance for any kind of dirt that could contaminate the chip-making process. According to The United Daily News (UDN), the foundry's longtime cleanroom equipment supplier is experiencing a shakeup in management.

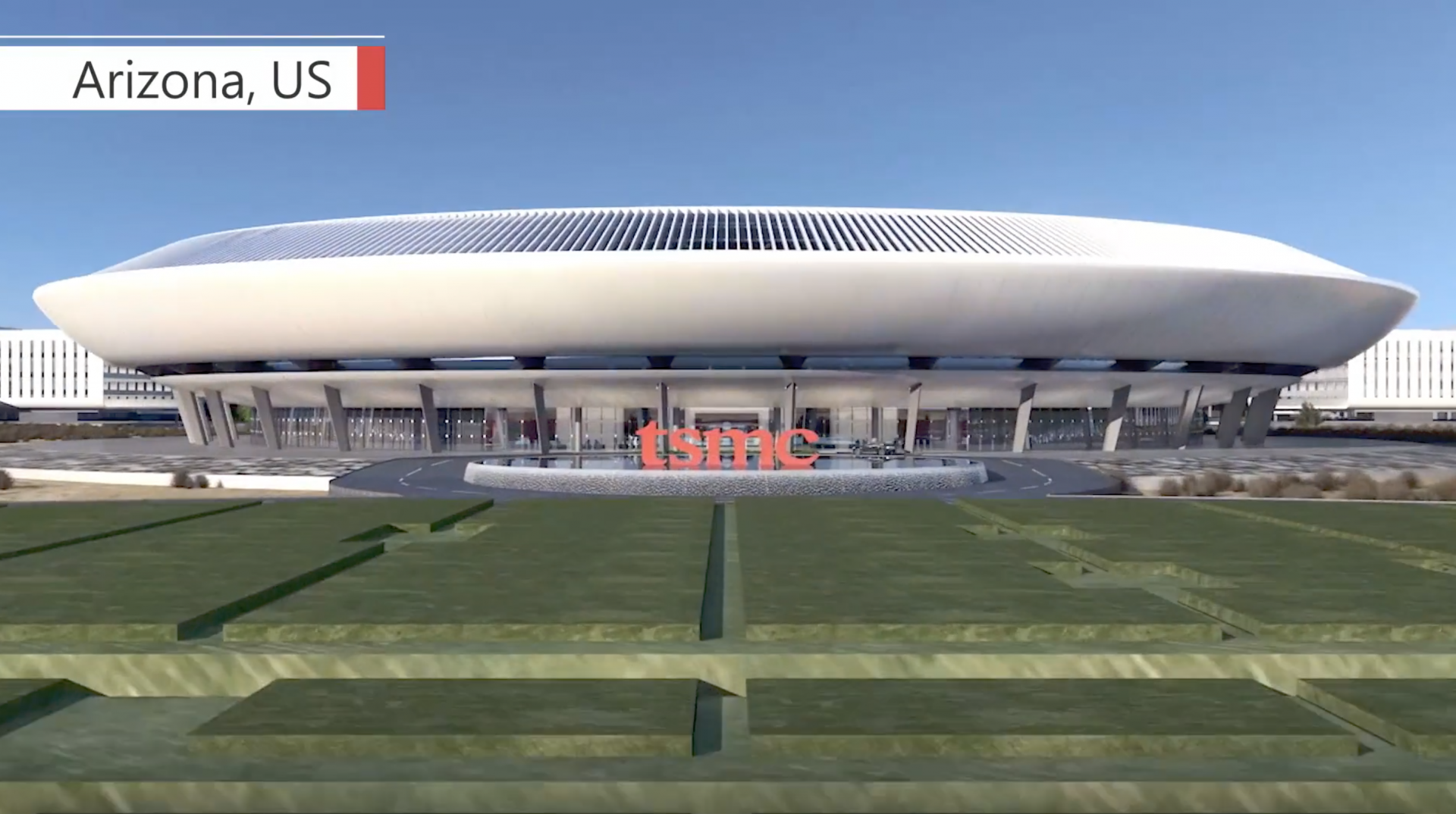

Render of TSMC's Arizona fab due to open in 2024. Image credit TSMC

Jiangxi Hantang System Integration Co. was going to equip the new TSMC Arizona factory with a clean room. But the company is in the middle of a major management shakeup led by its largest stockholders. What kicked off this instability was the death of Hantang's founder in 2015 which resulted in the widow receiving the majority of the company's stock.

Some of the contracts that Hantang has with tech companies, including the one with TSMC that will supply its U.S. fab with equipment for a clean room, are now part of the power struggle taking place inside Hantang. However, the latest rumor is that Hantang and TSMC have concluded their negotiations and that Hantang will send 20 of its top engineers to the U.S. and hire more than 200 people in the states to help it set up TSMC's U.S. facilities.

When the Arizona fab opens, mass production will take place using the 5nm process node. The facility is expected to produce 20,000 wafers per month. But there are whispers that TSMC will end up manufacturing chips using the 3nm process node while hiking output to 100,000 wafers per month. And if demand requires it, the U.S. might ask TSMC to build six factories in the states instead of just one. This has been confirmed by TSMC chairman Dr. Liu (Mark) Deyin.

The factory will cost TSMC $12 billion to build and back in April the company started hiring Americans, 250 of them to be sure. Of those hired, 100 were sent to Taiwan for training. Construction of the facility started to take place in June. The goal here, and one that was on the mind of then President Donald Trump, was to make the U.S. self sufficient when it comes to the manufacturing of chips.

Currently, a company like Apple might design its own chips. Since Apple is what those in the industry call fabless (meaning without a fabrication facility), the tech giant has a contract foundry like TSMC or Samsung manufacture its chip. As you might be aware of, there is a huge chip shortage affecting companies that depend on the Asian supply chain and this has been creating a shortage of components used in the automobile industry with some impact felt by companies that manufacture mobile devices.

U.S. tech firms do not want to rely on other countries to purchase chips

If the U.S. can get a better grip on supplying its own firms with semiconductors without having to rely on suppliers in China or in other overseas markets, it would be a feather in the cap not only for U.S. tech firms that need to purchase these components, but without having to resort to purchasing these parts from other countries. As former president Trump said in May 2020, "We shouldn’t have supply chains. We should have them all in the U.S."

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: