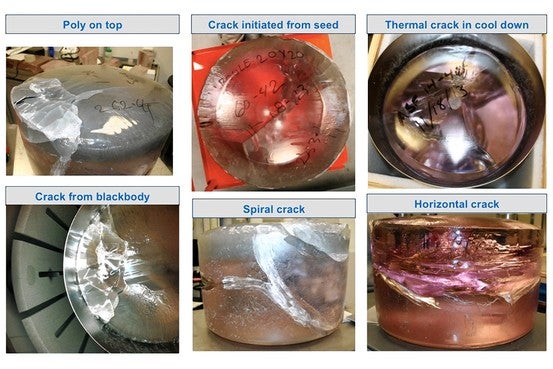

Ever seen cracked sapphire? Check out the photos of the broken glass Apple received from GT

"Money was flying out of the door."

In a strive to improve the production quality, and with Apple's trust, GT quickly hired an additional 700 staffers, which only led to mismanagement and chaos. Amidst the lack of an attendance policy and the establishment of unlimited overtime, hundreds of workers ended up having nothing to do, but sweep the floors and act busy to get paid. There weren't enough furnaces to operate, and in the words of one employee, "money was flying out of the door". However, the worst problem, and the most crucial too, was that the making of a single sapphire boule took as much as 30 days and cost $20,000. On top of that, more than half of the production was deemed unusable. That's a lot to write off!

In addition, GT (allegedly) lost three months of work time to power outages and facility building delays. In other words, a grand fiasco took form. Eventually, GT and Apple decided on making smaller cylinders, which almost got the production problems sorted out. However, a manager mistakenly sent 500 of the 14-inch thick bricks of material used to make iPhone screens to recycling, instead of shipping. They were discovered later, and no money was lost, but the work was protracted. By that time, it was clear that sapphire had to be scrapped altogether if the iPhone 6 and his compatriot were to be announced in September.

source: WSJ

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: