TSMC chairman backs away from selling chips to firms stockpiling them

As you probably know by now, there is a chip shortage that is plaguing the global electronics industry. Some companies, such as Apple, have been able to limit the fallout because of its position as TSMC's largest customer. The latter is the world's largest independent foundry and produces chips for some of the biggest names in tech including Qualcomm, Intel, AMD, and Nvidia.

TSMC chairman Mark Liu recently spoke with Time Magazine about the chip shortage which became an issue for manufacturers once the lead time stretched out to 15 weeks. The lead time measures how long it takes from the time a customer places an order to the time that the firm receives its chips. Yes, COVID-19 was responsible for the chip shortage, but not for the reasons that you might think.

TSMC tried to determine which of its customers were stockpiling chips

The story goes that because of the weak economy early last year (which was caused by the pandemic), carmakers reduced their orders for semiconductors from foundries likes TSMC. While this was going on, manufacturers started to stockpile chips as they became concerned about the U.S.-China trade war.

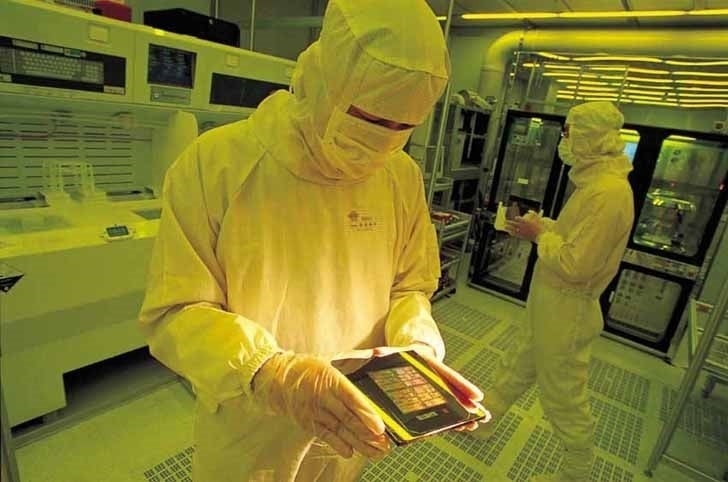

Fabs use yellow lights during the lithography process when etching circuit designs on wafers

The number of chips being shipped to factories outnumbered the number leaving these factories inside products. That led TSMC's Liu to say, "There are people definitely accumulating chips who-knows-where in the supply chain." The executive had his company figure out which of its customers were buying chips because they were needed immediately, and which firms were purchasing chips to hoard them.

TSMC's chairman noted that "We are learning too, because we didn’t have to do this before. Sometimes [customers] may not be satisfied, but we just have to do what’s best for the industry." Some of TSMC's highly valued customers had to wait for chips if it was determined that their needs were not urgent.

The chip shortage did shine a light on the industry and the president's $2 trillion infrastructure bill included $50 billion to make America more competitive in the industry. TSMC is planning to spend $100 billion over the next three years to hike capacity. While certainly a large amount of money, Liu responded by saying, "the more I look at it, it’s not going to be enough."

TSMC and Samsung are the only two foundries capable of producing chips using the 5nm process node. As more and more transistors are packed into chips (the A15 Bionic used on the iPhone 13 line carries 15 billion transistors) the manufacturing process gets more complex. This forced TSMC to delay the production of 3nm chips until the second half of next year forcing Apple to use the 4nm process node for next year's A16 Bionic. Samsung reportedly has also been forced to delay 3nm production to 2024.

The U.S. and China aim to become self-sufficient in the semiconductor industry

U.S. chipmakers like Intel and GlobalFoundries remain far off the pace set by TSMC and Samsung. The two U.S. foundries have fallen two or more process nodes behind the leaders. For Intel, the loss of process leadership is something it talks about recapturing. Daniel Nenni, co-author of Fabless: The Transformation of the Semiconductor Industry, says, "That’s disgraceful for Intel. It’s just very disappointing that they lost leadership."

While the U.S. and China both have failed to become self-sustaining when it comes to semiconductors, TSMC is in the process of building a $12 billion factory in Arizona that will churn out 5nm chips by 2024. While that process node won't be cutting edge by 2024, it still could be the first step toward building a competitive chip industry in the states.

The chip shortage has made many aware of the important role that these components play in our lives. And every other year, TSMC and Samsung feel the pressure to move on to the next process node making the production of semiconductors more and more complex. That alone is an arduous task.

Toss in a pandemic, political factors, and even a drought which reduced the availability of water (it takes 10 gallons of water to make a single chip) and you have a series of moving parts that executives like Liu need to deal with constantly.

Follow us on Google News

Things that are NOT allowed:

To help keep our community safe and free from spam, we apply temporary limits to newly created accounts: